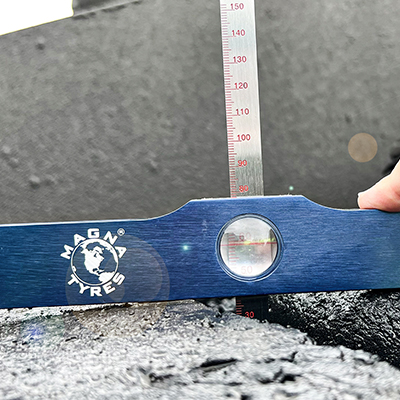

Tread Pattern and Tread Depth

Tread Depth & TRA Code

According to the Tire and Rim Association, Incorporated (TRA), there are three general classifications of tread thickness for Off-the-Road tyres: regular, deep and extra-deep. Deep and extra-deep are 1,5 and 2,5 times thicker than regular. The thicker treads have greater cut and wear resistance.

Although thicker treads give greater wear and cut resistance, they also generate and retain more heat. Accordingly, work conditions for tyres with thick treads should be thoroughly evaluated to prevent heat separation and other heat-related damage.

Deep and extra-deep tread tyres have almost the same overall diameter, which is larger than regular tread tyres. When replacing regular tread tyres with deep or extra-deep tread tyres, the larger overall diameters of the thicker tread tyres should be taken into consideration.

Rock Pattern Tread Design

The rock pattern is specially designed to prevent cuts caused by sharp rock. Its large ground contact area provides maximum wear resistance. Characteristic grooves running across the direction of the travel mark the most popular tread pattern for Off-the-Road tyres.

Traction Pattern Tread Design

The traction pattern tyre has a directional tread design, which means the direction of mounting on the rim is important. For example, the mounting direction should place the tread facing one way on the drive wheels to produce proper traction, while on the free rolling wheels, the tread should face the opposite direction.

Block Pattern Tread Design

The block pattern tyre is mostly characterised by wide tread width and rounded shoulders. Under heavy loads, the block pattern’s large ground contact area creates low ground contact pressure, for good flotation properties. Therefore, it is well suited for use on soft, muddy ground.

This pattern is also called the “alligator” or “button” pattern.

Rib Pattern Tread Design

The rib pattern tyre has grooves running parallel to the direction of travel and gives high directional stability. The rib-lug pattern, a variation of the rib pattern, has lugs on the shoulders of the tread. Rib pattern tyres are mainly used on free-rolling wheels.

Smooth Pattern Tread Design

The smooth pattern tyre, designed for tyre rollers, has no grooves. It is used for compacting and levelling. A smooth pattern tyre can also be used on loaders in underground mines because of its high wear and cut resistance. The smooth pattern for loaders, however, has two narrow grooves that are used to measure tread wear.

Highway and Off-road Tread Design

This long-lasting, non-directional tread design contributes to efficient fuel consumption and guarantees operating comfort for mobile cranes at highway and off-road usage.

Floatation Tread Design

Special floatation tread design optimised for agricultural / transport purposes for agricultural trucks and trailers.