Radial, Bias & Solid Tires – Construction Explained

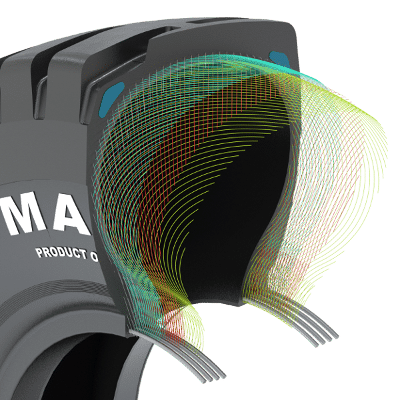

What is a Radial Tire?

Magna Tyres’ radial constructed tires utilize a series of steel cords, extending from the beads and across the tread, so that the cords are laid at approximately right angles to the center line of the tread, and parallel to each other, as well as belts directly beneath the tread. This network of cords gives the tire strength and shape.

Due to the all steel radial construction the sidewall of a radial tire is more flexible compared to a bias tire resulting in a shorter, but wider footprint. This means less rolling resistance, lower fuel consumption, more grip and greater ride comfort at greater speeds. Steel radial construction has no movement between plies, which means lesser heat build up or increased resistance to heating. Also the belts directly under the tread ensure lesser deformation which leads to more traction and puncture resistance.

Disadvantages of the radial tire include a harder ride at low speeds on rough roads and in the context of off-roading, decreased “self-cleaning” ability, a more rigid sidewall and lower grip ability at low speeds.

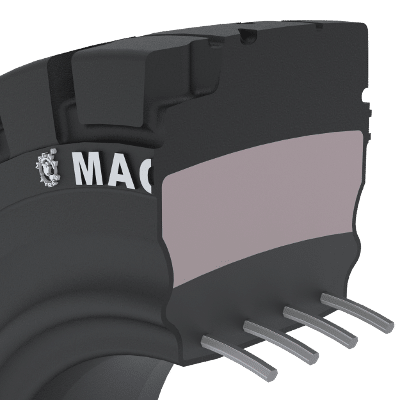

What Is a Bias Tire?

A Bias tire is made of layers of rubber-coated, plies of fabric (commonly nylon) placed at angles of approximately 30-40 degrees, with successive plies laid at opposing angles forming a crisscross pattern to which the tread is applied. This construction provides the main advantages: a smooth ride on rough surfaces with enhanced operator comfort, while also the ability to withstand higher loads. This makes these tires especially effective for machinery in ports & terminals.

On the down-side, these tires have lower grip at high speeds, are more sensitive to overheating, have accelerated wear and higher fuel consumption.

What Is a Solid Tire?

Solid tires are non-pneumatic, meaning that they are not filled with air. These tires are used for industrial applications and suitable for forklifts, heavy-duty transport vehicles, platform trucks and other industrial vehicles.

Recycling & waste companies and manufacturers who handle glass products are likely to use solids because of their resistance to puncture damage. They are extremely stable, maintenance-free and also able to handle a significantly higher weight load than pneumatic tires without the fear of blowouts.

Solid tires are especially designed for slow-moving industrial machines that require heavy lifting.