Role of Compactor in the industry

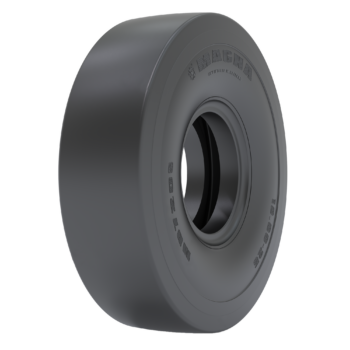

A compactor is a specialised machine engineered to compress, stabilise and consolidate soil, aggregates or waste materials in both construction jobs and intensive waste management operations, delivering enhanced substrate strength and uniform density to support structural reliability. As the machine must tolerate high static loads and repeated vibration cycles, the selection of tyres such as the MB720 and MB720S is fundamental to ensure consistent footprint stability, effective compaction and robust traction on varied surfaces.

Types of Tyres Used in these Machines

The specification of Compactor tyres depends on the compactor’s weight, drum configuration and operating environment; such tyres are engineered for smooth steel-drum, padfoot or pneumatic compactor machines and incorporate radial or bias constructions with reinforced sidewalls, thereby meeting the demands of travel over firm surfaces, vibration engagement and frequent directional changes.

Tyre Requirements for Reliable Performance

Tyres designed for compactors must deliver minimal deflection under heavy loads and vibration, maintain uniform contact pressure across the footprint, resist heat-build up during sustained operation and provide robust sidewall and tread durability against abrasion. Casing rigidity, compound optimisation for mixed surfaces and high puncture resistance are key technical attributes required to sustain continuous cycle performance in demanding compaction settings.

Questions? We're Always Ready.

Still have questions? Check the FAQs below or connect with one of our specialists.

Which tyre sizes are commonly used on compactors operating in heavy compression work?

Compactors typically use sizes such as 23.1-26 or 11.00-20, providing the footprint, load capacity and structural stiffness needed for consistent ground compression under continuous vibration.

How do operating surfaces influence tyre requirements for a compactor?

Because compactors run on soil, gravel and asphalt, tyres must deliver strong traction, stable sidewalls and wear-resistant compounds to maintain uniform compaction and predictable low-speed control.

Why is selecting the correct tyre size essential for compaction performance?

Correct sizing ensures proper rim fit, distributes pressure evenly across the drum-supporting axles, maintains machine stability and prevents premature wear during prolonged high-load compaction cycles.

Which tyre characteristics help maximise uptime for compactors in demanding daily use?