-

E4

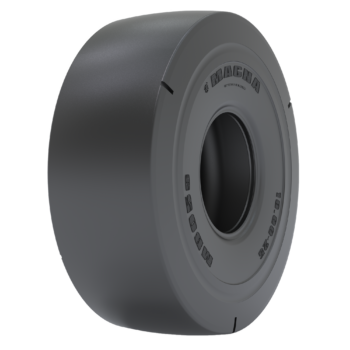

MA04+

Strong tyre with deep tread, specially designed for tough mining conditions.- 14.00R25

- 16.00R25

- 18.00R25 **

- 18.00R25 ***

- 18.00R33 **

- 18.00R33 ***

- 21.00R33 **

- 21.00R33 ***

- 21.00R35

- 24.00R35 **

- 24.00R35 ***

-

L5S

MB05S

Controlled traction on loose, shifting surfaces.- 14.00-24

- 17.5-25

- 18.00-25

- 26.5-25

-

IND

MB800

Pneumatic tyre with special compound provides comfort, efficiency and resistance in industry.- 5.00-8

- 6.00-9

- 6.50-10

- 7.00-12

- 8.25-15

- 28X9-15

- 250-15

- 300-15

- 10.00-20

- 12.00-20 (20)

- 12.00-20 (24)

- 355/65-15

-

IND-4

MR800+

Extra-deep tread provides traction and stability in industry and ports.- 9.00R20

- 10.00R20

- 12.00R20

- 12.00R24

- 14.00R24

- 16.00R25

Role of Underground Speciality Machinery in the industry

Underground speciality machinery includes a range of purpose-built machines designed to support production, haulage, scaling, bolting and utility tasks within confined Underground mines. These units operate in low-profile drifts, narrow crosscuts and areas with limited ventilation, requiring precise manoeuvrability and dependable traction. Because these machines work on abrasive rock surfaces and endure continuous cyclic loading, tyres such as the MB800 and MA40+ provide the durability, cut resistance and stability essential for safe and efficient underground operations.

Tyre Types Required for Underground Speciality Machinery Operations

Machines fitted with Underground speciality machinery tyres or operating on Shuttle car tyres demand reinforced tread patterns, high-impact sidewalls and robust casing constructions capable of absorbing shock loads from uneven tunnel floors. These tyres must support low-speed manoeuvring, heavy traction demands and tight turning within restricted spaces, ensuring predictable handling and reliable performance across the varied equipment categories found throughout Underground mines.

Tyre Requirements for Reliable Performance

Tyres for underground speciality machinery must resist cuts and abrasion from sharp rock, maintain structural rigidity under sustained weight and minimise heat build-up in poorly ventilated conditions. They require compounds engineered for slow-speed torque transfer, footprints designed to maintain grip on wet or fractured rock and controlled deformation to support precise movement in confined headings. Consistent stability, long tread life and reliable traction are essential to maintain safe, continuous and efficient operation in demanding underground mining environments.

Questions? We're Always Ready.

Still have questions? Check the FAQs below or connect with one of our specialists.

What defines underground speciality machinery in complex mining environments?

Underground speciality machinery includes purpose-built equipment such as scaling units, maintenance carriers and utility loaders. Their tyres must handle confined spaces, sharp rock, heavy loads and continuous low-speed manoeuvring.

How do underground operating conditions influence tyre requirements for speciality equipment?

These machines work on abrasive rock, wet tunnel floors and uneven ground, requiring tyres with strong cut resistance, reinforced sidewalls and dependable traction to maintain safe and predictable operation.

Which tyre sizes are commonly suitable for underground speciality machinery?

Suitable options often include compact heavy-duty sizes such as 10.00-20, 12.00-24, 14.00-25 or 16.00-25, providing the strength, footprint and durability needed in confined, high-risk mining environments.

Which tyre characteristics help maximise uptime for underground speciality machinery?