-

E3/L3

MA01

Tyre provides excellent grip on soft surfaces and long-lasting performance everywhere.- 17.5R25

- 20.5R25

- 23.5R25

-

E3/L3

MA01+

Multi-purpose E3/L3 performance for demanding earthmoving.- 17.5R25

- 20.5R25

- 23.5R25

- 26.5R25

- 29.5R25

-

E3+/L3+

MA02

All-position radial tyre for higher speeds, cut resistance and comfort.- 23.5R25

- 26.5R25

- 29.5R25

-

E3/L3

MA02+

Heavy-duty radial tyre for extreme terrains, traction, stability and protection.- 750/65R25

- 875/65R29

-

E4/L4

M-TRACTION

Delivers strong grip, stability and reliability in demanding mining operations.- 29.5R25

-

L4

MB450

Strong bias tyre delivering durability and traction in demanding earthmoving work.- 17.5-25

-

L5

MA05

Reinforced L5 tread delivers grip, reliability and protection in mining- 17.5R25

- 26.5R25

- 29.5R25

-

L5

MA07+

Super-deep L5 tread delivers maximum traction, stability and protection in mining- 35/65R33

-

L5

MA08

Extra-deep L4/L5 tread provides grip, wear resistance and protection in mining.- 17.5R25

- 20.5R25

- 23.5R25

- 26.5R25

- 29.5R25

- 29.5R29

- 35/65R33

-

L5

MA10

Deep L5 tread delivers excellent traction and protection in mining applications.- 20.5R25

- 23.5R25

-

L5

MA10+

Super-deep L5 tread provides maximum grip and wear resistance in mining- 15.5R25

- 17.5R25

- 20.5R25

- 23.5R25

- 26.5R25

- 29.5R25

-

L5

MB10

Extra-deep L5 tread provides traction and wear resistance in heavy mining- 26.5-25

-

G2/L2

M-SNOW

Unique winter tread provides optimal traction and safety in snow and mud- 17.5R25

- 20.5R25

- 23.5R25

-

E4/L4

MU26

Large tread provides grip, safety and stability in underground mines.- 26.5R25

- 29.5R25

-

E4/L4

MU30

Wide grooves and robust tread deliver grip and longevity in underground mining- 26.5R25

- 29.5R25

-

L5S

MA05S

Ultra-smooth L5 tread guarantees superior cut resistance in heavy mining- 17.5R25

- 18.00R25

- 26.5R25

- 29.5R25

- 29.5R29

- 35/65R33

-

IND

MR400

Radial design with steel belt ensures long life in construction and industry.- 460/70R24

- 500/70R24

- 540/70R24

- 400/70R24

- 400/80R24

- 440/80R24

- 440/80R28

- 480/80R26

-

E2/L2

MA11

Aggressive E2/L2 tread provides traction and protection in construction applications.- 365/70R18

- 405/70R18

- 405/70R20

-

IND

MB400

Extra-reinforced bias tyre for high stability in heavy construction applications.- 10.5/80-18

- 12.5/80-18

-

IND

MB260

Extra-deep lugs provide traction, durability and comfort in construction applications.- 405/70-20

- 405/70-24

-

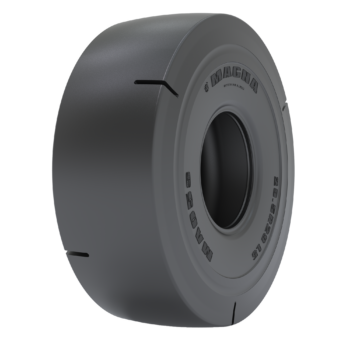

Solid

MA600

Solid tyre provides stability and resistance in heavy industrial applications.- 16.00-25

- 18.00-25

- 23.5-25

-

Solid

MA601

Solid tyre with deep tread provides stability in heavy industrial applications.- 17.5-25

- 20.5-25

- 23.5-25

- 26.5-25

- 29.5-25

- 35/65-33

-

Solid

MA608

Solid tyre with massive tread provides traction and stability in industry- 10.00-20 (7.00)

- 10.00-20 (7.50)

- 12.00-20 (8.00)

- 12.00-20 (8.50)

- 12.00-24

- 14.00-24

- 14.00-25

-

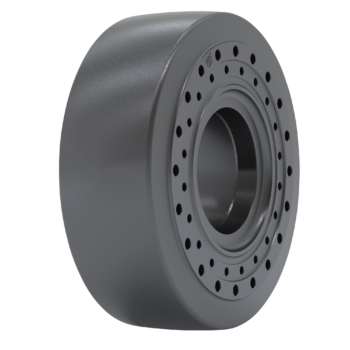

Solid

MA902

Smooth solid tread provides stability and reliability in heavy industrial environments.- 20.5-25

- 23.5-25

- 26.5-25

- 17.5-25

-

Solid

MA801

Solid tyre provides traction and safety in waste and recycling applications.- 30X10-16

- 33X12-16

- 33X12-20

- 36.5X14-20

Role of Wheel Loader in the industry

A wheel loader is a high-capacity loading and material-handling machine used across Construction sites, surface mines and underground mine transport operations for loading, stockpiling and short-distance hauling. Its articulated chassis and powerful breakout force make it suitable for demanding tasks ranging from quarry production to infrastructure work. Because wheel loaders operate on abrasive ground, carry variable loads and perform continuous loading cycles, tyres such as the MA08 and MU30 provide the stability, traction and structural strength needed for consistent performance in mixed heavy-duty environments.

Tyre Types Required for Wheel Loader Operations

Machines fitted with Wheel loader tyres or operating on Loader tyres require reinforced tread patterns and sidewall constructions capable of handling high torque, uneven terrain and continuous lifting cycles. These tyres must deliver predictable ground contact and stability for loaders working alongside equipment such as a backhoe loader or compact wheel loaders, ensuring safe operation on rocky surfaces, compacted soil or paved work zones typical of construction sites, surface mines and underground mine transport areas.

Tyre Requirements for Reliable Performance

Tyres for wheel loaders must resist cuts, abrasion and impact from rocks while maintaining structural integrity under heavy lifting and repeated loading cycles. They require durable compounds to manage heat build-up during long shifts, a footprint that ensures maximum traction on loose or compacted materials and controlled deformation to support precise manoeuvring under load. Strong lateral rigidity, consistent pressure distribution and high resistance to chunking are essential to maintain safe and efficient wheel loader performance in severe working environments.

Questions? We're Always Ready.

Still have questions? Check the FAQs below or connect with one of our specialists.

What defines a wheel loader in heavy material-handling work?

A wheel loader is a powerful loading machine used to move soil, aggregates or bulk materials. Its tyres must absorb high breakout forces, maintain traction and support constant forward–reverse cycles on challenging ground.

How do operating surfaces influence tyre requirements for a wheel loader?

Wheel loaders work on gravel, rock, soil and uneven jobsite terrain, demanding tyres with strong cut resistance, deep tread and lateral stability to maintain safe loading performance under heavy torque.

Which tyre sizes are commonly suitable for wheel loaders in construction and quarry operations?

Typical choices include 17.5R25, 20.5R25, 23.5R25 and 26.5R25, offering the load capacity, footprint and durability required for high-cycle loading, stockpiling and short-haul material movement.

Which tyre characteristics help maximise uptime for wheel loaders in daily operation?