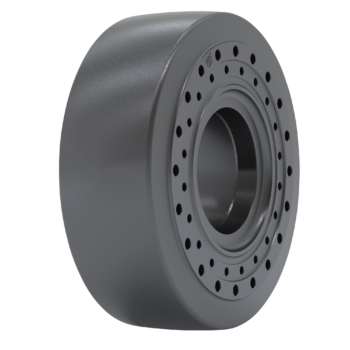

Waste & Recycling Tyres

Magna Tyres is committed to reducing the environmental impact of waste tyres by supporting responsible disposal and reuse. Through innovative solutions, we promote recycling tyres into valuable resources that contribute to a cleaner and more sustainable future.

Read more