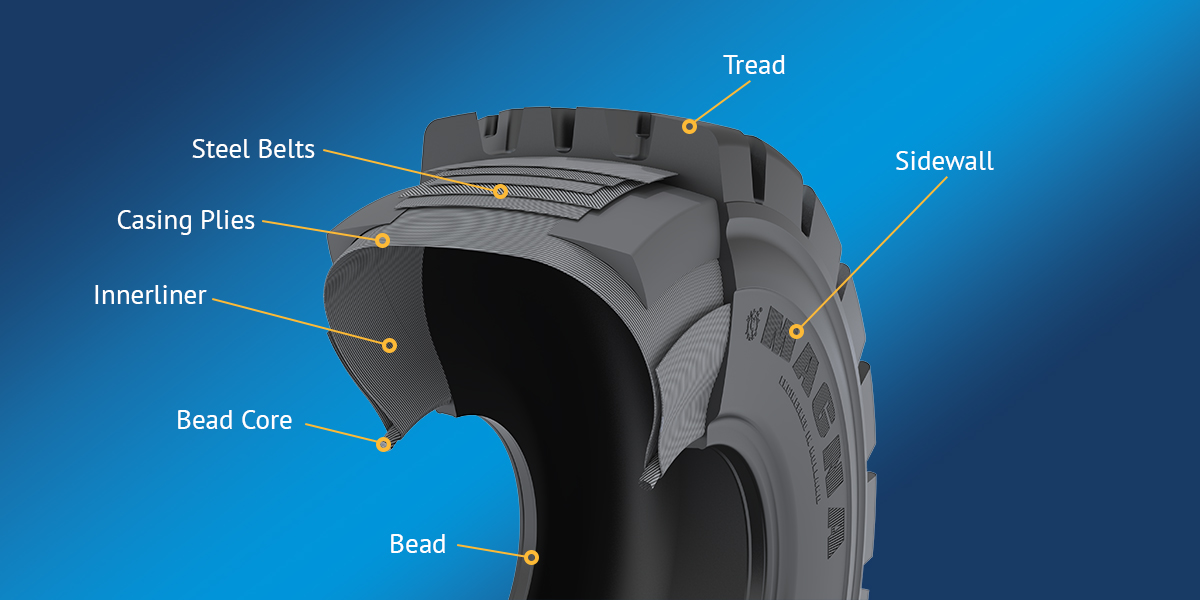

Anatomy of a Tyre

What Makes Up an OTR Tyre?

Tread Pattern – Grip & Application-Specific Design

This is the outside layer and is the part of the tyre that comes in contact with the (road) surface. It is designed with patterns specific to the tyre’s use to provide traction. Tread patterns come in a large variety of forms, depending of the usage of the tyre. Tread patterns come in different classes and within the OTR industry they are divided into the following categories: C for Compactor, E for Earthmover, G for Graders and L for loaders/dozers. Within these categories, the tyre is marked with a number varying from 1 to 7 to indicate how deep or sturdy the tread pattern is. Very handy if you need to decide what specific tyre to use! You can read all about it in this article.

Sidewall – Balancing Comfort and Load Capacity

The sidewall is, as the name suggest, the side of the tyre. This extends from the edge of the tread pattern tot the bead. It offers lateral stability and has a big influence in the amount of driver/operator comfort the tyre provides. In general, the sturdier a sidewall is, the more weight a tyre can carry. Unfortunately that also means the tyre is less forgiving for imperfections in the road surface, meaning a less comfortable ride for the operator. A tyre always has a fine balance between sturdiness and comfort, depending on the application it was designed for.

Steel Belts – Reinforcement for Stability & Puncture Resistance

These are layers of steel wires coated with rubber. These steel belts are placed under the tread pattern to provide stability and to make the tread pattern puncture-resistant. The steel belts in the tyre also help the tyre to stay flat and in shape under load, overall improving the sturdiness of the tyre.

Casing Plies – Strength vs. Heat Build-Up

These are the layers of fabric making up the body of the tyre, also adding to the strength and flexibility of the tyre. Casing plies are usually made from materials such as nylon, polyester or rayon cords. Weight and strength are the two main factors in deciding what type of fabric is being used. It always comes down to the right balance for the specific task the tyre is developed for. A heavier tyre is stronger, but will also suffer from quicker heat build-up in the tyre during operations, affecting the tyre’s wear resistance. Tyre weight also has a big influence on the vehicles fuel consumption, which will have a direct impact in the total cost per hour of the tyre (TKPH). Ever wondered how to calculate the TKPH? Check out this article.

Inner Liner – Air Retention in Tubeless Tyres

As the name suggest, this is the innermost layer of a tubeless tyre, which retains the air inside. This effectively replaces the function of an inner tube.

Bead & Bead Core – Anchoring the Tyre to the Rim

The bead is where the tyre is anchored to the wheel rim. Obviously, this needs to be a very strong seal as it also traps the air inside the tyre and rim. The bead is a thick and strong piece of rubber with a steel cord within the bead. This steel cord is unsurprisingly called the bead core and is essential for keeping the tyre on the rim. The flexibility of the rubber combined with the strong core means the tyre grips around the rim perfectly.

Want to Learn More?

Tyres are our passion and we love to share our knowledge. We frequently publish white papers in an easy to read format to so you can learn more about our world. Make sure to check out our other articles on our Academy page and subscribe to our newsletter so you’ll be among the first to receive our next white paper!