-

IND-3

MB01

Stable performance under continuous heavy loading.- 16.00-25

- 21.00-25

- 18.00-33

- 21.00-35

-

IND-4

M-STACKER

Deep tread with reinforced casing provides stability and traction in ports.- 18.00-25

-

IND-4

M-STACKER+

Extra-deep tread and improved compound provide load capacity and longevity in ports- 18.00-25

-

IND-4

MB02

Deep tread and strong carcass provide traction and stability in ports.- 11.00-20

- 12.00-24

- 14.00-24

- 18.00-25

- 18.00-33

-

IND

MB800

Pneumatic tyre with special compound provides comfort, efficiency and resistance in industry.- 5.00-8

- 6.00-9

- 6.50-10

- 7.00-12

- 8.25-15

- 28X9-15

- 250-15

- 300-15

- 10.00-20

- 12.00-20 (20)

- 12.00-20 (24)

- 355/65-15

-

IND-4

MR800+

Extra-deep tread provides traction and stability in industry and ports.- 9.00R20

- 10.00R20

- 12.00R20

- 12.00R24

- 14.00R24

- 16.00R25

-

Solid

MA600

Solid tyre provides stability and resistance in heavy industrial applications.- 16.00-25

- 18.00-25

- 23.5-25

-

Solid

MA601

Solid tyre with deep tread provides stability in heavy industrial applications.- 17.5-25

- 20.5-25

- 23.5-25

- 26.5-25

- 29.5-25

- 35/65-33

-

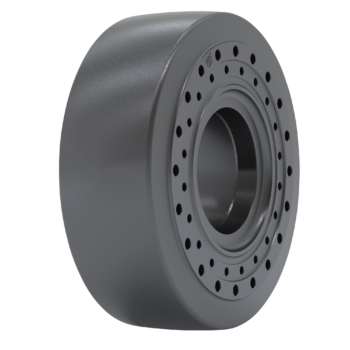

Solid

MA608

Solid tyre with massive tread provides traction and stability in industry- 10.00-20 (7.00)

- 10.00-20 (7.50)

- 12.00-20 (8.00)

- 12.00-20 (8.50)

- 12.00-24

- 14.00-24

- 14.00-25

-

Solid

MA608 TWIN WHEEL

The solid twin-wheel tyre provides traction, safety, and stability in industrial applications.- 10.00-20

- 12.00-20

- 12.00-24

- 14.00-24

- 14.00-25

-

Solid

MA902

Smooth solid tread provides stability and reliability in heavy industrial environments.- 20.5-25

- 23.5-25

- 26.5-25

- 17.5-25

Role of Material Handler in the industry

A material handler is a specialised lifting and sorting machine designed to manage bulk materials, scrap, timber and waste streams across Construction environments and heavy Recycling settings. Its elevated cab, long reach boom and continuous grab cycles demand high stability, predictable ground contact and strong load management. Because these machines operate on mixed and uneven surfaces while carrying significant upper-structure weight, tyres such as the MB01, M-STACKER and MA608 provide the structural support, traction and casing rigidity needed for safe and efficient on-site performance.

Types of Tyres Used in these Machines

Machines fitted with Material handler tyres require tread patterns and constructions that can withstand repeated slewing, continuous lifting cycles and exposure to abrasive ground conditions typical of Construction and Recycling settings. These tyres must balance strong sidewall reinforcement with a footprint that maintains stability during boom movements, ensuring controlled travel and dependable handling on paved yards, compacted soil or debris-covered surfaces.

Tyre Requirements for Reliable Performance

Tyres on material handlers must support substantial upper-structure mass with minimal deformation, provide consistent traction during positional adjustments, and resist heat build-up from low-speed, high-load operations. They require a reinforced casing to absorb lateral forces produced by continuous swing motions, along with a tread compound engineered for wear resistance in abrasive recycling yards. Stability, cut protection and uniform pressure distribution are essential to maintain safe lifting precision and uninterrupted operational throughput.

Questions? We're Always Ready.

Still have questions? Check the FAQs below or connect with one of our specialists.

What is a material handler and where is it typically used?

A material handler is a specialised machine used to load, move and sort bulk materials in recycling, scrap yards and industrial sites. It requires tyres that support heavy lifting, high stability and frequent manoeuvres.

What operating conditions do material handlers face that affect tyre selection?

They work on uneven surfaces, scrap piles and industrial yards where tyres must resist cuts, handle heavy machine loads and maintain traction during repeated lifting and turning operations.

Which tyre sizes are commonly suitable for material handlers in heavy industrial environments?

Typical options include sizes such as 10.00-20, 12.00-24, 14.00-25 or 23.5-25, offering the load capacity, footprint and robustness required for elevated handling work and repetitive swing movements.

Which tyre characteristics help maximise uptime for material handlers under demanding workloads?