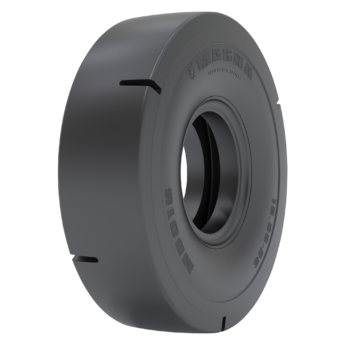

Port & Terminal Tyres

Designed for the most severe applications to handle heavy loads at high speeds.

Read More

Port and terminal machines are expected to work hard in handling freights and goods every day. Ports and terminals require specialised tyres to support the various operations and handling of cargo, including loading and unloading of shipping containers, transportation within the port area, and manoeuvring in tight spaces. Magna Tyres has terminal tyres and port tyres for many machines, which are especially designed for the most demanding conditions.

The machines for ports and terminals need to carry heavy weights, often more than indicated. Container handlers, for instance, must be able to cope with the extreme height reach of their loading masts. This creates a heavy load on the front axle. The rear tyres also come under pressure, as they have to ensure vehicle stability. The complexity of all vehicles in this category and their extremely heavy loads require extremely robust tyres. We offer tyre solutions for the following machines:

Material handling hubs and harbours are a special environment where wear resistance and cost-effectiveness are the key elements of a tyre. To meet the special requirements of port and terminal tyres, the Magna Tyres portfolio is especially designed for:

Discover our tyre range above for your perfect tyre solution.

Still have questions? Check the FAQs below or connect with one of our specialists.

What tyre construction is optimal for reach stackers and rubber-tyred gantry cranes?

Both radial and bias constructions serve port equipment effectively. The M-TERMINAL+ radial offers superior heat dissipation and shock absorption for demanding operations, whilst the MB01S bias provides exceptional load capacity and stability. Selection depends on operational intensity, load requirements and equipment specifications.

How do port tyres maintain stability during high-level container stacking operations?

Port tyres feature reinforced casings and special compounds engineered for high air pressure resistance. Wide, strong rib patterns ensure exceptional stability, whilst advanced casing technology minimises container mast swaying. This combination delivers secure load platforms and enhanced operator comfort during elevated stacking.

What tread depth is necessary for terminal tractors operating continuously in container yards?

Terminal tractor tyres typically feature extra-deep tread profiles ranging from 30mm to 76mm depending on application severity. Deep, ribbed tread patterns provide superior resistance to damage whilst extending service life. Sizes like 310/80R22.5 and 12.00-24 accommodate varying operational demands.

Which factors affect tyre selection for straddle carriers versus empty container handlers?

Straddle carriers require maximum load distribution and stability over longer distances, typically using sizes like 16.00R25 or 450/95R25. Empty container handlers prioritise manoeuvrability and frequent acceleration, often utilising smaller sizes. Both applications demand robust sidewalls and damage-resistant construction for reliable operation.